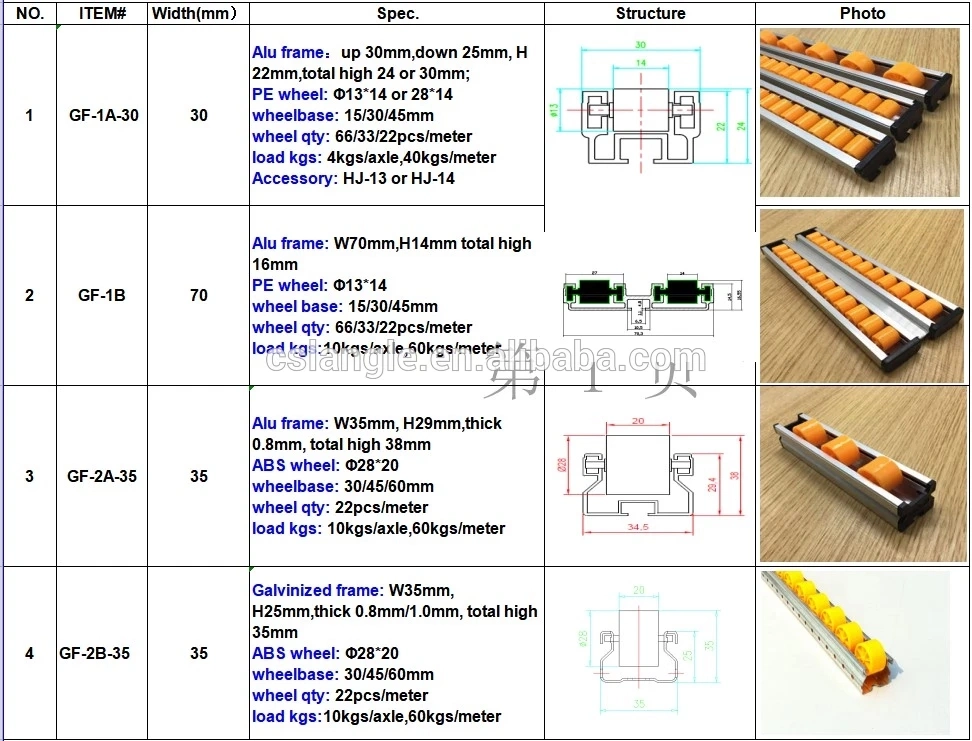

Aluminum Alloy Roller Track for Pipe Rack System Conveyors

Aluminum Alloy Roller Track for Pipe Rack System Conveyors Roller track are used mainly for the safe movement of transpo

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | GF-4B-40 |

| Materials | Aluminum Frame, PE Wheel |

| Product Name | Aluminum Alloy Roller Track |

| Transport Package | Carton Box |

| Specification | customized size |

| Trademark | Langle |

| Origin | China |

| Production Capacity | 10000PCS/Month |

Product Description

Aluminum Alloy Roller Track for Pipe Rack System Conveyors

Roller track are used mainly for the safe movement of transport boxes and cartons in flow racking.The rolles are made of premium quality, robust, impact resistant thermoplastic, It absorbs no damp and is resistant to acids and leaches,. These rollers, on steel axies, are available as standard or as flanged rollers.

The roller track frame is cold formed zinc plated steel 1.5mm thick

Product Features:

1. Maily applied as flow rack's slide rail, could also as guardrail and guide of conveyor

2. Simple stryture, running smoothly

3. When applied as side rail, the inclination decided by weight and bottom of goods, normally 3-6.

4. Normally evey 600-800mm has a support frame.

| Model | R13 | R28 | R28D |

| Wheel:diamaterXwheel wide | 13X14 | 28X25 | 28X25 |

| Frame: hightXwidth | 21.5X29.7 | 34.2X40.9 | 34.2X40.9 |

| Total height | 23.5 | 38.5 | 43.5 |

| Lengthen | 1000/1500/2000 | 1000/1500/2000 | 1000/1500/2000 |

| Wheel spacing | 15/30/45 | 30/45/60 | 45/60 |

Product Description

Fluency

A fluent bar is also called a slideway. There are mainly sheet metal fluency bars and aluminum alloy fluency bars. Because of its convenient installation and placed the articles above the running smooth and agile, as the name suggests it is called a fluency, many of them are used in the material rack of the workshop, etc.

Please contact us for more sizes and specification as per your request.

Carton flow live storage racks can be designed, supplied and installed to your own specification.

1) Live storage systems

2) Order picking

3) Cell feed stations

4) Just in time systems

5)gravity flow conveyors

6) Stock rotation

7) Kanban shelving

Kanban shelving with rollertrack conveyor

Roller track(New Range)

Standard duty(plain rollers)

Heavy duty (plaiin & flanged rollers)

Heavy duty ESD(plain & flanged rollers)

We also have other series roller track

40 series

60 series

85 series

We also have other material series roller track

Galvanize

Aluminum

Some information for roller track, placon

LANGLE Product Information | |

Product description | Aluminum profiles acccessories, Fluency bar |

Applications | Advanced first out shelf, Racking system belt conveyor idler roller , flexible production line, Warehouse flow rack, roller production line, carton flow rack & shelves, gravity flow rack, FIFO flow storage etc, Conveyors, etc |

The option of Sizes | 40/30/20 |

Material | Sheet metal, aluminum alloy, aluminium profile |

Roller Material | PE/ABS/ESD/PLASTIC |

Roller Color | White / yellow / Black / Blue |

Length | 4 meters / root (customized) |

Standard | GB, ISO |

Quality Guarantee | More than 5 Years Quality Guarantee |

Certification | ISO9001 |

OEM and ODM | Acceptable |

Function and Connecting detail

1. Cutting the size of aluminium profile with designed.

2. Select suitable accessories to connecting the aluminium profile for the kits.

3. Langle can help select to the accessories if you are not clear which size to use.

4. And if you are the new of using aluminium profile, just tell us the function of the kit you want to build, so we can recommend the suitable size of materials to use and also provide the design service.

.

FAQ

Q1: Are you a factory or trading company?

A: We're a self-own factory, can offer a full range of services: product design, manufacturing, stocking, and delivery on time which enable us to be your "one-stop" shop.

Q2: Can you Send me a sample?

A: Yes, we can send you samples, samples are free and freight is on your side.

Q3: Do you have any MOQ limit for order?

A: Low MOQ, 1pc for sample checking is available.

Q4: What's the production time for new moulds and mass production?

A: 7~10 days to open the new moulds, mass production takes around 20~25days for one 20GP, 25~30days for one 40HQ, can process urgently if needed.

Q5: How about the length for the profile?

A: Any custom-tailed lengths available. Max length of profiles are 6.02 meter longs.

Q6: Do you have accessories for the profile?

A: We are able to supply full accessories for the profile.

Q7: What is the payment terms?

A: Telegraphic Transfer(T/T) and Letter of Credit (L/C) are acceptable.

Q8: What certification do you have?

A: We are certificated by ISO 9001, factory is reliable and good quality can be guaranteed.

Related Products

-

![Ksm]()

Ksm

-

![Belt Conveyor Pulley Self Aligning Steel/Rubber/HDPE Return Trough Carry Carrying Carrier Conveyor Idler Roller Price for Cement/Port/Mine/Coal/Power Plant]()

Belt Conveyor Pulley Self Aligning Steel/Rubber/HDPE Return Trough Carry Carrying Carrier Conveyor Idler Roller Price for Cement/Port/Mine/Coal/Power Plant

-

![Industrial Bulk Fixed Gravity Roller Powered Radial Mobile Truck Loading Corrugated Sidewall Chevron Rubber Belt Conveyor for Coal Mining Cement Quarry Crusher]()

Industrial Bulk Fixed Gravity Roller Powered Radial Mobile Truck Loading Corrugated Sidewall Chevron Rubber Belt Conveyor for Coal Mining Cement Quarry Crusher

-

![Belt Conveyor Concrete Batching Plant Belt Conveyor Steel Conveyor Roller]()

Belt Conveyor Concrete Batching Plant Belt Conveyor Steel Conveyor Roller